CCTV IT Support at Blue Ocean Bar, Port Barton. Introduction. On-site IT installation and network preparation activities were carried out at the Blue Ocean Bar located in Port Barton, Palawan. The purpose …

CCTV Supply and Installation at ACS Manufacturing Corporation -- 5th Progress.

Introduction

Progress at ACS Manufacturing Corporation continues to move steadily forward as our team enters a new area of the site for the next batch of CCTV infrastructure installation. This week’s work focused on expanding the network of junction boxes and flexible hose conduits with Cat6 cables, bringing our surveillance system closer to full coverage across the facility.

While previous work established the foundation in initial zones, this latest effort ensures that additional critical areas are being prepped for camera deployment, maintaining consistency, protection, and scalability throughout the entire site.

Expanding to a New Area.

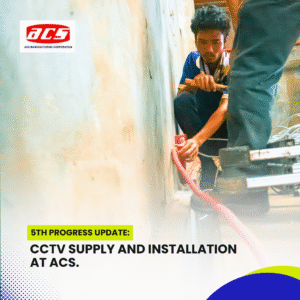

Having completed junction box connectivity in the first zone, our technicians turned their attention to a new section of the site as outlined in the pre-approved CCTV layout plan. This new area—equally dynamic and essential to ACS operations—required a fresh round of preparation, beginning with drilling anchor points for junction boxes and planning flexible conduit routes.

Our team began by drilling precise mounting holes into concrete and steel surfaces, using industrial-grade equipment to create solid anchors for junction boxes. As always, placement followed the original camera blueprint, ensuring line-of-sight coverage and optimal viewing angles for the upcoming CCTV units.

Orange PVC junction boxes—chosen for their visibility and durability—were mounted at each designated location using heavy-duty wall anchors and brackets. These enclosures will serve as the central node for power and data cabling to each camera in this section.

Flexible Hose and Cat6 Cabling.

With junction box placement underway, our team followed up by installing new flexible hose conduits, each containing Cat6 Ethernet cables. These hoses provide a protected channel for the cables, ensuring that the wiring remains secure against mechanical stress, vibration, dust, and moisture—particularly important in high-traffic or equipment-heavy areas.

Each hose was measured and cut to fit the unique layout of the new zone, factoring in bends, height variations, and clearance requirements. Technicians carefully routed the hoses from the central cable path to their corresponding junction boxes, anchoring each section neatly to overhead beams or walls.

The Cat6 cables, which support both high-speed data and PoE (Power over Ethernet), were carefully pulled through the hoses and sealed into the junction boxes. All connections and routes were documented and labeled for future reference and maintenance.

Conclusion

This fifth phase marks the beginning of full-site integration at ACS Manufacturing Corporation, as we expand our installation efforts to additional sectors of the facility. By continuing the systematic placement of junction boxes and the routing of Cat6 cabling within flexible conduit, we are reinforcing the reliability and scalability of the CCTV system.

With more areas now prepared, we move closer to complete surveillance readiness across the entire compound. The next step will focus on finalizing these connections and preparing the network for camera deployment and NVR integration. Stay tuned as we bring this project into its final stages.

Case Studies

CCTV Site Inspection at Punched Coffee, Ayala. Introduction. Closed-Circuit Television (CCTV) systems play a vital role in maintaining security, monitoring daily operations, and ensuring the safety of both staff and customers in …

CCTV Support at ilao-ilao, JMall Introduction. Closed-Circuit Television (CCTV) systems are vital for maintaining security, monitoring daily activities, and protecting property and personnel. These systems rely on continuous and stable video recording …